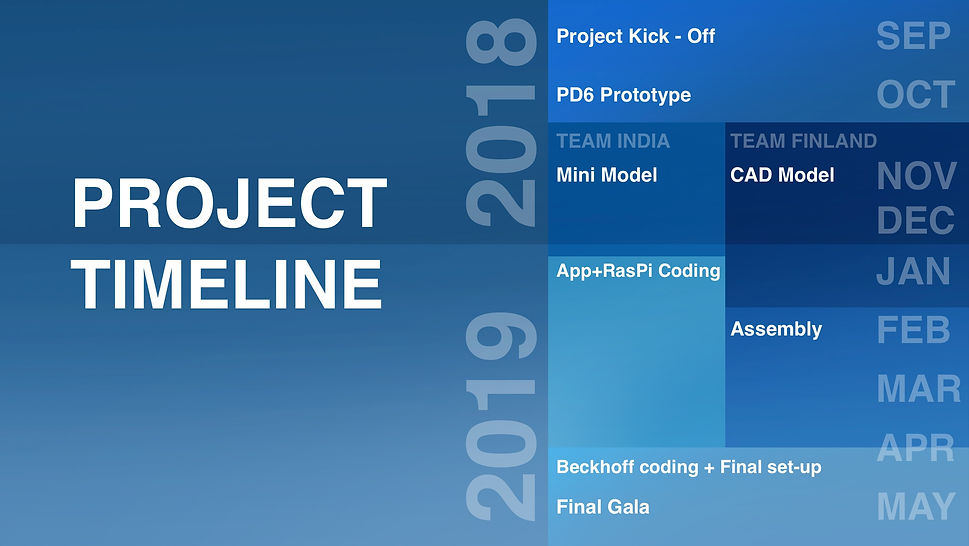

September 2018 - May 2019

FREELEVATOR

Using Mecanum wheels to move multiple elevator cars both vertically as well as horizontally in an elevator shaft

Overview

Client:

Kone

Duration:

September 2018 - May 2019

Methods:

Product Development, Arduino and Raspberry Pi Coding

Team:

Project Lead (2)

UX and Electronics Designer

Visual Designer

Industrial Designer (5)

Tools:

Skype, Microsoft Office, Adobe Photoshop, Adobe Illustrator, iMovie, Arduino IDE, Android Studio

Introduction

The project is a part of the Product Development Project (PDP) course conducted by the Aalto University Design Factory, Helsinki in collaboration with multiple Design Institutions across the globe along with local and international industry partners.

The PDP program has over 100 students participating from more than 20 Design Factories across the globe. The Design Factory Global Network is a network of innovation hubs in universities and research institutions across five continents.

Each team is an interdisciplinary team with students from Science, Technology, Social Sciences, Engineering, Design and Business backgrounds.

This multi-disciplinary team is a team of four students who were pursuing the Post Graduate Diploma in Design and Innovation at the Indian School of Design and Education (ISDI), Mumbai.

The local team from Finland comprised of five Master’s students from Aalto University, Helsinki.

The Interdisciplinary and Cross-Cultural Team

Project Brief

The problem statements are given by both domestic and foreign industrial companies, who are in search of innovative cooperation with the next generation of product developers.

The team was given a design brief to redesign an elevator transport mechanism using Mecanum wheels, such that multiple elevator cars can move in one shaft structure simultaneously, in both, the vertical and horizontal direction.

Understanding the Limitations

-

With an increase in population, there is a large demand for multistorey residential spaces, which means taller and multiple elevator shafts, reducing living space

-

Higher power consumption

-

Heavier metal cables and weights in the pulley system of an elevator, limit the height of the shaft

-

Elevator mobility is restricted in the vertical axis

Potential Applications

-

Skyscrapers

-

For transportation of luggage on cruise liners, the outer circumference of the ship could be used for these elevators

-

Construction sites

-

With the expansion of airports, elevators moving on the same horizontal level will be the future of transportation

Mini Model

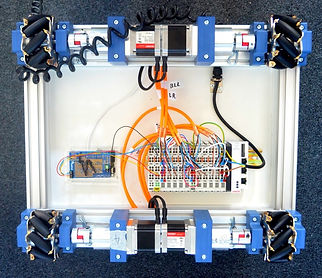

Team India designed and developed a Mini Model of the working prototype using Omniwheels and an electronic circuit comprising of Arduino boards, motor drivers, DC motors, and Bluetooth modules. The friction between the walls and the rollers of the wheels was tested along with the identification of the torque required to raise the car within the shaft.

3D Render of Mini Model

Prototyping with the Omniwheels, there was low friction between the rubber rollers of the Omniwheel and the surface of the shaft. Therefore, Mecanum wheels were used in the final prototype for maximum friction and the least wear and tear of the rollers on the circumference.

Working Prototype of Mini Model

Coding the Remote Controlled App

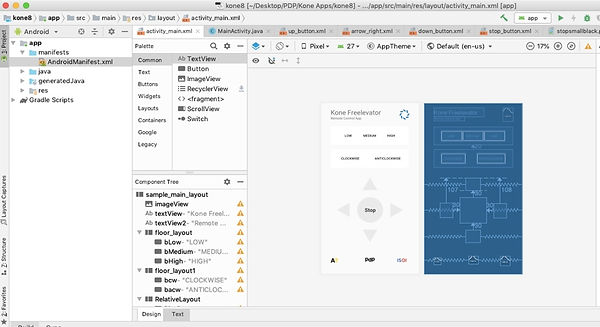

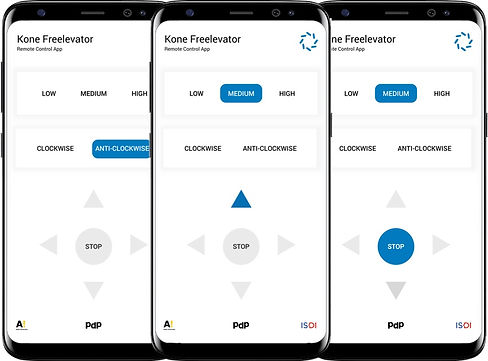

The final prototype was controlled with a remote-controlled mobile application designed and developed by Team India using Android Studio App Developer. The interface was designed on Sketch.

There are speed controls, direction controls along with a stop function to control the movement of the elevator car.

Raspberry Pi 3B+ board was used in the final prototype for controlling the directions and speed of the elevator car via Bluetooth connection.

Movement of the Mecanum Wheels

CAD Model of Elevator Car

Final Elevator Car with Electronics

Final Working Prototype

Team Finland designed the CAD model and built the final working prototype.

Electronics for the final working prototype was provided by Beckhoff Automation, Finland.

Controls and Operations of the final working prototype were developed by the entire team.

Raspberry Pi coding for each of wheels was done such that the wheels would move in the vertical axis - up and down, horizontal axis - left and right, as well as clockwise and anticlockwise.

The team designed a logo and came up with a tagline as well!